Capital Improvement Projects

The District is committed to enhancing the condition of its water system through wise and sound investments in capital improvement projects. Some of the projects improve the performance of the water system while other projects extend the life of existing facilities and equipment. All improvement projects are well planned for and are selected based on the best value to the District’s Customers. It is the District’s responsibility to identify the needed improvements and we do so by periodically updating the District’s Water Master Plan. This plan helps to identify needed improvements and ranks them based on their benefits. Please see a copy of the District’s 2017 Water Master Plan.

Some of the District’s more notable capital improvements include the following projects:

Nitrate Treatment System

In Progress

The District is currently working to construct a treatment facility to treat Nitrate in the groundwater supply. The project is anticipated to be completed and operational in early 2023. In recent years, Nitrate levels at the District’s Groundwater Wells have been on an increasing trend. Nitrate is a widespread contaminant in groundwater throughout the nation. LPVCWD is committed to removing nitrates with this innovative treatment process. The project construction is anticipated to be completed in the Spring of 2022 and the treatment facility will be full permitted and operational in the Fall of 2022.

Recycled Water Project

In Progress

Construction of the recycled water distribution pipeline and pump station was completed in July 2020. The District is currently working with customers in the area to retrofit existing irrigation systems to utilize recycled water. The Recycled Water System is designed to deliver 55 acre feet of local recycled water for irrigation use. This will decrease the District’s dependency on import water for groundwater replenishment and minimize the impact of the rising cost of replenishment water.

District’s Well No. 5 Rehabilitation Project

2020

The District completed this well rehabilitation project in February of 2020. This project consisted of replacing the pumping equipment in its Well No. 5, which will extend the life of the well and improve the efficiency of the pumping equipment. Maintaining the District’s wells provides better water supply reliability.

5th Street Waterline Improvement Project

2019

The District completed this waterline improvement project in August of 2019. This project consisted of the installation of approximately 600 feet of 12-inch waterline to improve reliability and fire flow capacity on 5th Street and Workman Avenue.

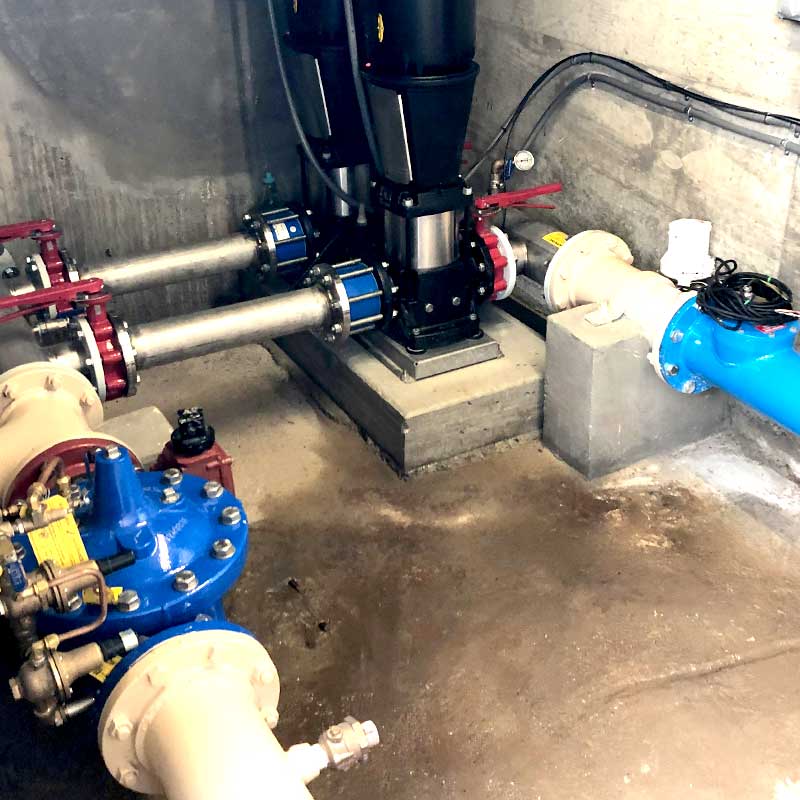

Banbridge Booster Pump Station Project

2018

This project consisted of rehabilitating an aging inefficient pump station by replacing the pumping system to improve reliability of service to the District’s service zone 3.

Zone 2 Booster Station Piping Improvements

2013

This project consisted of replacing old piping at the station site to improve the reliability and efficiency of the booster pumps.

Zone 3 Improvement Project

2012

This project improved the water pressure reliability and flow capacity of the District’s Zone 3. The improvements included a new 10 inch waterline connection to the Industry Public Utilities Water System’s reservoirs on Industry Hills. The new connection allows Zone 3 to be supplied even when there is a power failure. It also acts as an emergency back-up supply for the District’s Zone 2.

Zone 4 Booster Pump Station Upgrades

2011

This project was constructed to reduce pumping costs and improve the reliability and capacity of the pumping system.

Single Pass Ion Exchange System

2010

This project was constructed to replace the older less efficient ion exchange treatment system. This new water treatment system uses resin material that is designed for the selective removal of the contaminant perchlorate. This process is much like a household water softening system. However, this system does not require regeneration using salt water, like most other ion exchange processes. In addition, this new system produces virtually no wastewater and is estimated to have the resin replaced every 6 to 9 months.

Main Street Reservoir Relining and Re-coating

2009

This project consisted of the removal and replacement of the reservoir’s interior coating and painting of the exterior. This investment adds many years to the service life of the reservoir.